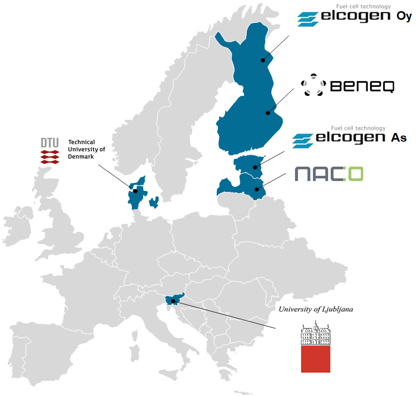

Consortium

Technical University of Denmark

The Technical University of Denmark (DTU) is one of Europe’s foremost technical universities, with approximately 5000 employees of which more than half are scientific staff members including more than 1000 PhD students. DTU Energy has now more than 200 employees and holds world class expertise in fuel cells (solid oxide fuel cells and polymer electrolyte fuel cells), electrolysis cells, batteries, hydrogen storage, and “power-to-X” related technologies.

DTU Energy has experience since 1987 in solid oxide cell research and development. Currently approximately 40 persons work directly on SOFC and SOEC related national and international projects, including materials development, cell manufacturing and advance characterization and testing.

DTU Energy also holds extensive research experience on electro-synthesis of chemicals such as methanol, ethanol and ammonia involving suitable catalyst and polymer membranes.

Role in the PilotSOEL project

In the PilotSOEL project, DTU will coordinate the project efforts in developing innovative routes for SOEL manufacturing. DTU will develop eco-friendly cell manfucture routes via water-based tape casting and wast tapes recycling. DTU will also bring in its expertise in electrochemical characterization and advanced microstructural analysis techniques for investigating the performance and durability of the developed cells and stacks.

Elcogen AS

Founded in 2001, Elcogen is a manufacturer of clean energy technology that delivers affordable green hydrogen and emission-free electricity. We are a European business with a proud Estonian heritage and a global customer network delivering flexible core solid oxide. Elcogen has its registered office in the UK, and manufacturing facilities in Estonia and Finland that have served 160 customers in 30 countries.

Elcogen develops and supplies the technology that sits at the heart of energy security and transition away from fossil fuels. We are focused on driving net-zero ambitions forward with a core, reversible technology that converts fuel sources into emission-free energy and emission-free energy into green hydrogen. Our solid oxide fuel cell (SOFC) and solid oxide electrolyser cell (SOEC) technology offers an efficient solution to green hydrogen production, reducing commercial costs so customers can deliver affordable energy solutions to meet net-zero targets.

Role in the PilotSOEL project

Elcogen AS will participate in the PilotSOEL project as a developer and industrial manufacturer of solid oxide cells, with a goal to improve the technology by increasing its efficiency and durability for high-current electrolysis operation. Work on reducing the use of CRM through optimizing layers and recycling production wastes is foreseen as well.

Also, the company expects to reach the very ambitious goal via a tight collaboration with research and industrial partners, leaders in their respective areas of thin layer deposition processes and cell testing and characterisation. The final goal is to produce upgraded cells and supply it for stack assembly for further validation via stack testing.

Elcogen OY

Elcogen is a developer and manufacturer of Solid Oxide Cell (SOC) technology – an efficient solution for green hydrogen production through electrolysis and emission-free power generation with fuel cells. We supply the core technology that sits at the heart of energy security and transition away from fossil fuels.

Elcogen’s SOC technology is flexible and can be applied to a broad range of residential, industrial, and commercial applications, enabling multiple types of systems to produce and use green energy.

Elcogen Group consists of Elcogen OY in Finland and Elcogen AS in Estonia. Elcogen OY focuses on the development, sales and pilot production of SOC stacks and modules for both fuel cell and electrolyser applications. Company was originally founded 2009 as a fully owned subsidiary of Elcogen AS.

Currently, Elcogen OY employs more than 30 persons, with largest team working in the R&D activities. SOC stack pilot production utilizes European supply chain for different stack components, however stack assembly and end-of-line testing are made in house.

Role in the PilotSOEL project

The main role of Elcogen OY in the PilotSOEL project is to develop SOEL stack manufacturing process towards full automatization with integrated quality control, to pave way for cost-efficient mass production of SOC electrolysers. Also novel interconnect coatings developed by Naco and Beneq will be tested in Elcogen OY’s stacks. Elcogen OY leads Work Package 3 “Optical inspection system (OIS) for stack assembly automation and quality assurance” and Work Package 7 “Dissemination, Communication and Exploitation”.Beneq is a manufacturer of atomic layer deposition (ALD) equipment and the home of ALD. In 1984, we established the world’s first industrial production using ALD. Today, we lead the market with ALD equipment products for R&D (TFS200, TFS500), semiconductor device fabrication (Transform®, Transform® 300, and ProdigyTM), 3D and batch production (P400A, P800, P1500), ultra-fast spatial ALD (C2R), and roll-to-roll ALD (Genesis).

Beneq’s unique Development Service simplifies customer adoption and proof-of-concept for new ALD processes, while its Coating Service cuts down time to market by outsourcing state-of-the-art ALD production. Beneq's engineers and experts are dedicated to making ALD tools accessible to researchers. The company’s headquarters is located in Espoo, Finland.

Role in the PilotSOEL project

In the PilotSOEL project, Beneq are developing ALD coatings as protective barrier layers for Solid Oxide Electrolysers (SOEL) cells, with the goal of upscaling the processes to industrial level in their P800 ALD tool.Naco Technologies, a pioneering startup based in Riga, Latvia, is leading the charge in transforming green hydrogen production. With a focus on advanced material solutions and innovative coating technologies, Naco aims to boost efficiency and affordability in hydrogen production systems.

In a significant move in 2023, Naco unveiled a cutting-edge pilot line capable of producing 500,000 coated components yearly, marking a major step forward in its mission to reshape the green energy sector. Notably, Naco secured a prestigious €10 million EIC Accelerator grant, further fueling its efforts in developing specialized nano-coatings and materials for electrolyzers and fuel cells.

Setting itself apart through a commitment to excellence, Naco prides itself on delivering top-notch thin film quality, leveraging advanced magnetron sputtering techniques for precision and consistency. With expertise in simulation and manufacturing, Naco fine-tunes processes for optimal results, achieving reduced coating thickness compared to other methods, thus enhancing efficiency and sustainability in hydrogen production.

Role in the PilotSOEL project

In the PilotSOEL project, Naco mainly focuses on delivering advanced protective coatings for interconnects' fuel and air sides and pioneering thin barrier layers for solid oxide cells, showcasing its dedication to innovation in solid oxide electrolysis.The University of Ljubljana (UL), Faculty of Mechanical Engineering, Laboratory for heat and power, has more than 15 years of experience with life cycle assessment (LCA) methods and techno-economic analysis of various energy conversion systems and technologies.

In the last 12 years, UL has been mainly involved in EU-funded projects in the field of fuel cell and hydrogen technologies (FCH) as leader of work packages (WPs) focused on environmental sustainability assessment and has been involved as LCA expert.

Over the last five years, UL has expanded its knowledge of incorporating sustainability assessment methodologies, especially in relation to FCH technologies, with knowledge of LCA, Life Cycle Cost (LCC) and Social LCA (S-LCA).

UL works as a leading expert with multinational and domestic companies in the digitalization of environmental impacts in the company's value chains. With its knowledge and experience, UL will actively collaborate in all working groups and with partners to create innovative life cycle inventories to be used and presented in work packages devoted to LCA and techno-economic analysis of novel SOEL stacks.

Role in the PilotSOEL project

The main task and objective of the UL in the PilotSOEL project is to perform a techno-economic analysis (TEA) and LCA assessment of the upscalable production processes and to evaluate the environmental and economic performance of the existing and novel SOEL technology.

In the manufacturing phase, new processing methods such as water-based tape casting in conjunction with cell microstructure optimization and optimization of advanced PVD and ALD protective barrier layer processing will be evaluated in the manufacturing phase of the SOEL stack.

Improved performance and lifetime as well as reduced use of critical raw materials (CRMs) in SOEL production will reduce the environmental impact per kg of hydrogen produced, which will be assessed by UL using the LCA and LCC methodology.

For evaluation and quantification, the results will be benchmarked with state-of-the-art technologies for H2 production (e.g. AEL, PEMEL).

As one of the most important results related to the sustainability assessment, the new innovative, not yet existing life cycle inventories for SOEL technology will be created, which will serve for future sustainability assessments of these technologies. In addition, proposed concepts for end-of-life (EoL) strategies without detailed LCA assessment will be presented and evaluated in the context of a techno-economic analysis that provides an estimate of the levelized cost of hydrogen (LCOH) when using renewable electricity.