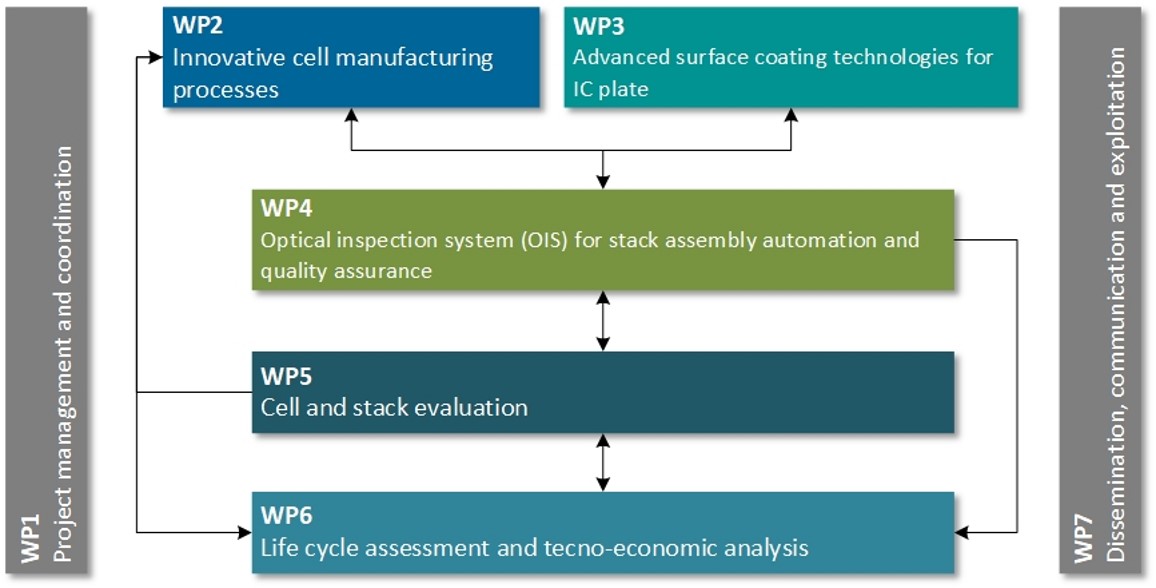

The project

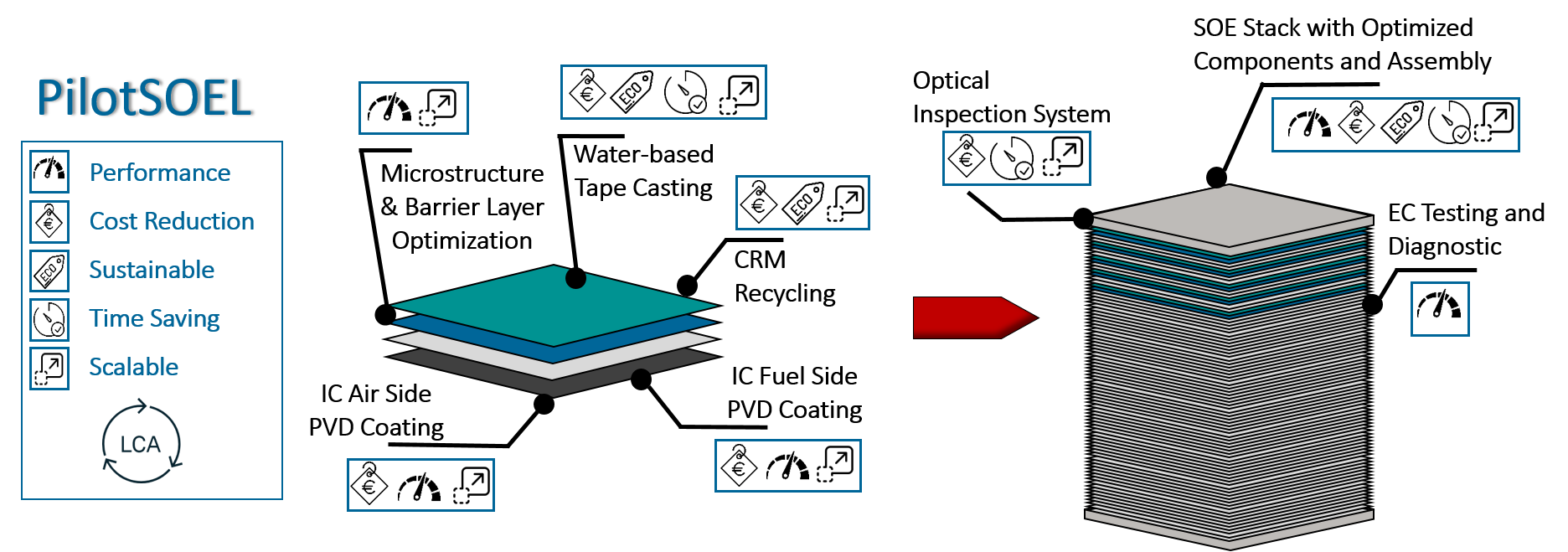

The project will focus on innovative upscalable and low-cost SOEL component manufacturing processes with reduced use of Critical Raw Materials (CRM) and waste recycling in the cell production processes, and increase the degree of automation in the stack assembly to reduce manufacturing cost.

The project will develop a novel environmentally friendly water-based tape casting process with a reduced number of process steps for half-cell production. Innovative thin protective barrier layers deposited by Atomic Layer Deposition (ALD) and Physical Vapor Deposition (PVD), together with microstructural cell optimisation, will reduce the cell resistance, improving the cell performance and durability at high current operation.

The dense and thin coating made by PVD will improve the oxidization resistance of the interconnector, allowing the use of cheaper alloys, and ensuring a long stack lifetime. A life-cycle assessment (LCA) and a techno-economic analysis (TEA) will be performed to benchmark the developed processes in PilotSOEL with the SoA SOEL production processes.

The project is aiming to improve the SOEL processing Manufacturing Readiness Level (MRL) from MRL 4 at the beginning of the project to at least MRL 5 at the end of the project.

The project's main objectives:

- Environmentally friendly novel water-based tape casting process for SOEL half-cell production

- High-performing and durable cells with effective protective coating applied by PVD and ALD

- Recycling process for unsintered waste materials

- PVD process for mass production of interconnect coatings

- Improvement of stack assembly automation and quality inspection

- Demonstration of the technologies’ readiness for mass production of an SOEL processing route with reduced CAPEX and OPEX values